NEWS

Thermal Transfer CTP Plate-chalco

Writer: admin Time:2024-01-25 15:56 Browse:℃

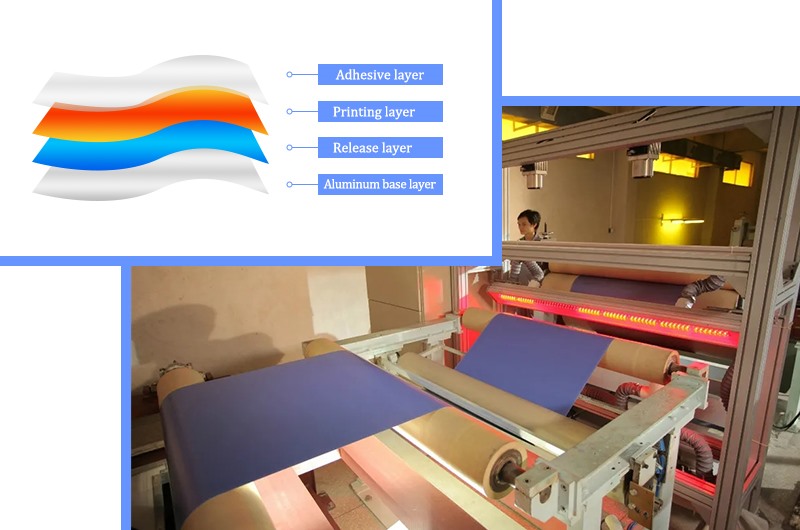

The structure of Thermal Transfer CTP Plate is generally divided into four layers, namely adhesive layer, printing layer, release layer and base layer.

The functions of the four-layer structure of Thermal Transfer CTP Plate are:

Base layer: It is the carrier of the thermal transfer film, that is, the carrier coated with release agent, ink and adhesive. Generally, the carrier is required to be resistant to high temperature, high pressure and small tensile deformation. There are many carriers of thermal transfer film, including PVC, PP, PET, but the most widely used is PET polyester film, referred to as PET film. It is a colorless, transparent and glossy film with excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, high temperature and low temperature resistance, chemical resistance, oil resistance, air tightness and fragrance retention Good, it is one of the commonly used barrier composite film substrates. In the structure of thermal transfer film, PET has the characteristics of low deformation rate under high temperature, good stability and good release, especially in the reproduction of color tone originals, it has better printing suitability, and High production efficiency in the process of thermal transfer.

Release layer: coated with release agent, which is a low-viscosity transparent resin with release, film-forming and adhesive properties. It remains in a solid state at room temperature, and can be melted and flowed when heated to a certain temperature. The release agent is one of the keys to complete the separation of the printing layer from the base layer and transfer the graphics to the surface of the substrate. It requires the release agent to have good release properties, not only to allow the printed layer to be peeled off from the base layer, but also to be completely and accurately peeled off.

away without any residue. At the same time, the release layer needs to have good wear resistance, which can protect the printing layer and reduce the invasion and corrosion of the ink layer by some substances in the air.

Printing layer: It is a layer of printing ink, which reproduces the color and tone level of the picture and text. Through the separation of the release agent, the printed layer can be completely transferred to the substrate, reflecting the final effect of the printed matter. During the printing process of the printing layer, the color ink is generally printed first, and then the white ink is printed, so that during the transfer process, the color ink is placed on the white ink.

Adhesive layer: its basic performance is that during the heating process, the adhesive layer melts and the surface of the substrate produces a greater cohesive force, which glues the printing layer and the substrate to ensure the combination of the printing layer and the surface of the substrate. firm. The adhesive of the adhesive layer should be matched with the printing material. Different adhesives, due to different chemical compositions, are combined with different substrates, and the adhesive force varies greatly. Different substrates should match adhesives with different compositions to ensure the bonding force between the adhesive layer and the substrate.

CTP PLATES

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan