Processless CTP Plate

1 The Product introduction of Processless CTP Plate

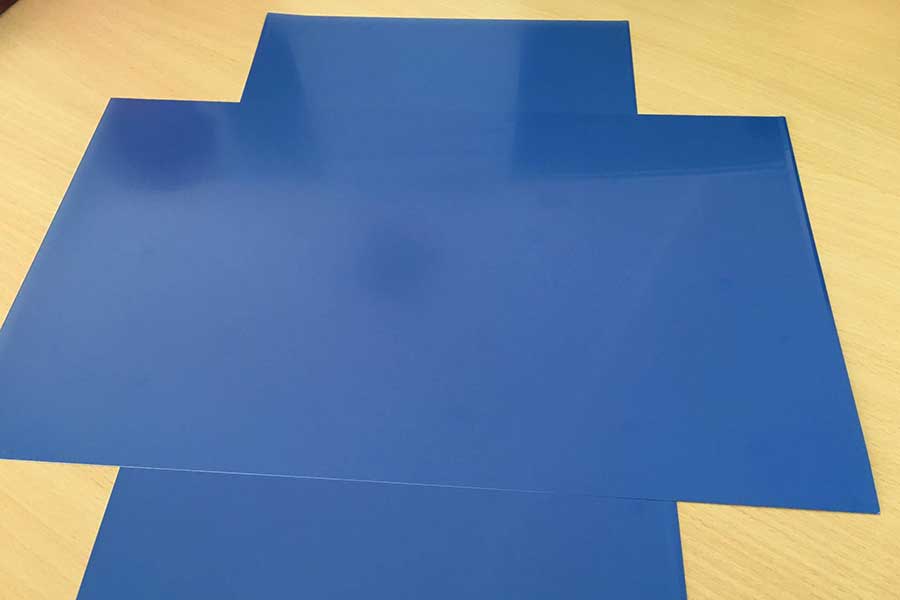

The Processless CTP Plate produced by Henan Chalco is by no means any other Processless printing plate on the market today. This is a breakthrough technology that combines the high performance of wet processing plates with Henan Chalco ’s leading Processless technology to create the printing plate is comparable to the processing type printing plate in the aspects of printing volume, imaging speed, operating durability, and resolution.

2 The Technical Parameters of Processless CTP Plate

Plate type: Non-ablation, Thermal, Positive(write portrait), Processless CTP Plate, no required dust removal and cleaning system

Application: High quality long version printing, suitable for sheet paper, packaging, rotary press and all UV printing applications

Base material: electrolytic grinding and anodizing aluminum Substrate

Alloy temper: 1060, 1050A, 1100 H18

Thickness: 0.15mm, 0.20mm, 0.30mm and 0.40mm

Available specifications: various specifications, or according to customer’s specifications

Maximum width: 1350mm

Spectral Sensitivity/Photosensitive wavelength: 800-850nm

Plate-making machine compatibility: Direct plate-making machines of all mainstream suppliers are compatible

Sensitivity/Exposure energy: 120mJ / cm², the highest production capacity can be achieved on most plate-making machines.

Resolution: 1-99% @ 200lpi; up to 450lpi, depending on the capabilities of the imaging device

Run Length:

Up to 400,000 impressions, hot-set / commercial cold-set rotary printing press

Up to 200,000 impressions, sheet-fed printing press

Up to 100,000 impressions, printing and packaging (non-UV ink)

Up to 75,000 impressions, UV ink application

Depends on image resolution, printing press, printing chemicals, ink and paper conditions

Safety light: white light = 2 hours

C20UV isolation = 16 hours

G10 yellow light = 48 hours

3 The Product Advantages of Processless CTP Plate

1) The Processless CTP Plate produced by our company will open a green future

Companies that use our Processless CTP Plate will become environmental pioneers, leading the way in saving water, reducing energy consumption, and eliminating chemicals. The Processless CTP Plate produced by our company is a true Wash Processless printing plate, which is made directly after the machine comes out, you can print on the machine and cancel any intermediate processing steps. Users will avoid the cost of processing, eliminate the production of related wastes, free up production space, cancel variables in processing, and avoid wasting time and money in printing.

2) The longest Run Length of Processless CTP Plate

In most applications, the Processless CTP Plate produced by our company can replace the non-baking wet processing plate, which can be up to 400,000 impressions in rotary printing and 200,000 impressions in single sheet printing. In UV ink applications (including low-energy UV) can even reach 75,000 impressions.

3) The Processless CTP Plate produced by our company has the characteristics of high productivity, high printing quality and high operation durability

The Exposure energy required for our Processless CTP Plate is only 120mJ / cm², so almost all direct plate-making machines can run at the highest capacity, and because of the elimination of the washing process, the plate-making speed is significantly accelerated. In addition, because this is a for more sustainable products, customers will also benefit from it, creating an environmentally friendly image, coupled with the characteristics of high resolution and operational durability of the modified plate, the resulting print quality is also very good.

4 The Usage of Processless CTP Plate

The Processless CTP Plate produced by our company is suitable for offset printing packaging (including food packaging), UV and low-energy UV printing, hot-set and cold-set rotary applications, high-quality commercial printing, and ultra-large format applications.

5.The Packaging of Processless CTP Plate

The packaging of Processless CTP Plate produced by our company: two coated faces are placed facing each other, separated by neutral backing paper in the middle, the outside is covered with plastic lined black kraft paper and placed in the carton box,each carton box is loaded around 50 -100 pieces,

Then stack the loaded carton boxes neatly on the wooden pallet and protect them with wooden frames or cardboard.

Finally, wrap it with kraft paper or plastic film and tighten by plastic tapes.

Or Packed according to customer requirements.

The Processless CTP Plate produced by Henan Chalco is by no means any other Processless printing plate on the market today. This is a breakthrough technology that combines the high performance of wet processing plates with Henan Chalco ’s leading Processless technology to create the printing plate is comparable to the processing type printing plate in the aspects of printing volume, imaging speed, operating durability, and resolution.

2 The Technical Parameters of Processless CTP Plate

Plate type: Non-ablation, Thermal, Positive(write portrait), Processless CTP Plate, no required dust removal and cleaning system

Application: High quality long version printing, suitable for sheet paper, packaging, rotary press and all UV printing applications

Base material: electrolytic grinding and anodizing aluminum Substrate

Alloy temper: 1060, 1050A, 1100 H18

Thickness: 0.15mm, 0.20mm, 0.30mm and 0.40mm

Available specifications: various specifications, or according to customer’s specifications

Maximum width: 1350mm

Spectral Sensitivity/Photosensitive wavelength: 800-850nm

Plate-making machine compatibility: Direct plate-making machines of all mainstream suppliers are compatible

Sensitivity/Exposure energy: 120mJ / cm², the highest production capacity can be achieved on most plate-making machines.

Resolution: 1-99% @ 200lpi; up to 450lpi, depending on the capabilities of the imaging device

Run Length:

Up to 400,000 impressions, hot-set / commercial cold-set rotary printing press

Up to 200,000 impressions, sheet-fed printing press

Up to 100,000 impressions, printing and packaging (non-UV ink)

Up to 75,000 impressions, UV ink application

Depends on image resolution, printing press, printing chemicals, ink and paper conditions

Safety light: white light = 2 hours

C20UV isolation = 16 hours

G10 yellow light = 48 hours

3 The Product Advantages of Processless CTP Plate

1) The Processless CTP Plate produced by our company will open a green future

Companies that use our Processless CTP Plate will become environmental pioneers, leading the way in saving water, reducing energy consumption, and eliminating chemicals. The Processless CTP Plate produced by our company is a true Wash Processless printing plate, which is made directly after the machine comes out, you can print on the machine and cancel any intermediate processing steps. Users will avoid the cost of processing, eliminate the production of related wastes, free up production space, cancel variables in processing, and avoid wasting time and money in printing.

2) The longest Run Length of Processless CTP Plate

In most applications, the Processless CTP Plate produced by our company can replace the non-baking wet processing plate, which can be up to 400,000 impressions in rotary printing and 200,000 impressions in single sheet printing. In UV ink applications (including low-energy UV) can even reach 75,000 impressions.

3) The Processless CTP Plate produced by our company has the characteristics of high productivity, high printing quality and high operation durability

The Exposure energy required for our Processless CTP Plate is only 120mJ / cm², so almost all direct plate-making machines can run at the highest capacity, and because of the elimination of the washing process, the plate-making speed is significantly accelerated. In addition, because this is a for more sustainable products, customers will also benefit from it, creating an environmentally friendly image, coupled with the characteristics of high resolution and operational durability of the modified plate, the resulting print quality is also very good.

4 The Usage of Processless CTP Plate

The Processless CTP Plate produced by our company is suitable for offset printing packaging (including food packaging), UV and low-energy UV printing, hot-set and cold-set rotary applications, high-quality commercial printing, and ultra-large format applications.

5.The Packaging of Processless CTP Plate

The packaging of Processless CTP Plate produced by our company: two coated faces are placed facing each other, separated by neutral backing paper in the middle, the outside is covered with plastic lined black kraft paper and placed in the carton box,each carton box is loaded around 50 -100 pieces,

Then stack the loaded carton boxes neatly on the wooden pallet and protect them with wooden frames or cardboard.

Finally, wrap it with kraft paper or plastic film and tighten by plastic tapes.

Or Packed according to customer requirements.

CTP PLATES

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan