Positive Thermal CTP Plates

1. Introduction of Positive Thermal CTP Plate Products

CTP (computer to plate) refers to the technology that the graphic information on the layout is digitally processed and output directly to the printing plate without going through the process of making the film. The pre-press staff does not need to output the film after typesetting, and directly forms the image through the CTP plate making machine to the CTP plate, it is convenient to realize the full digital workflow from pre-press to printing and post-press.

Henan Chalco’s Positive Thermal CTP Plate combines all the excellent performances, high sensitivity, high print resistance, and UV-resistant ink. It is an ideal choice for high-end printing users.

2, The Technical Parameters of Positive Thermal CTP Plate

Product Name: Positive Thermal CTP Plate

Alloy temper: 1060, 1050A, 1100 H18

Thickness: 0.15mm- 0.4mm

Available specifications: various specifications, or according to customer’s specifications

Maximum width: 1350mm

Spectral Sensitivity/Photosensitive wavelength: 800-850nm

Sensitivity/Exposure energy: 100-130mj / c㎡

Resolution: 1-99%

Developing temperature 23 ± 2 ℃

Developing time:20-30 seconds

Safety light: The safe operation time of the room can be 2-4 hours

Run Length: 50,000-100,000 impressions (Unbaked) 100,000-200,000 impressions (Baked)

Shelf life: 24 months

Storage conditions: temperature 5-30 ℃, humidity 40 ~ 80% RH, protected from light, moisture, closed and stored, stack height <1.2m

3. The Product Advantages of Positive Thermal CTP Plate

1) The Positive Thermal CTP Plate produced by our company has strong stability

Our company has advanced production technology and strict quality control management to ensure the stable and consistent product performance and to ensure the high quality and stability of printed products.

2) The Positive Thermal CTP Plate produced by our company has fast plate-making speed, low energy and high speed, which maximizes the production capacity of the equipment and improves work efficiency.

3) The Positive Thermal CTP Plate of the dots produced by our company is accurately restored without correction, and the dot error does not exceed 1%. The application range of the equipment is expanded and the quality of plate-making is stable. It is perfectly suitable for plate-making equipment of 800 ~ 850nm.

4) The Positive Thermal CTP Plate produced by our company has high run length, and can reach 100,000 impressions without baking, and 200,000 impressions after baking.

5) The Positive Thermal CTP Plate produced by our company is easy to use. It operates in a bright room, does not require preheating, has high tolerance and strong adaptability, is not easily affected by changes in the working environment and operation, and is convenient for storage and transportation.

6) The Positive Thermal CTP Plate produced by our company reduces printing cost, high plate-making speed, high work efficiency, good water-ink balance performance, less paper consumption, fast ink application, and high ink use efficiency.

4, The Usage of Positive Thermal CTP Plate

The Positive Thermal CTP Plate produced by our company is compatible with all mainstream thermal plate-making machines in the market, and is widely used in packaging and exquisite commercial printing.

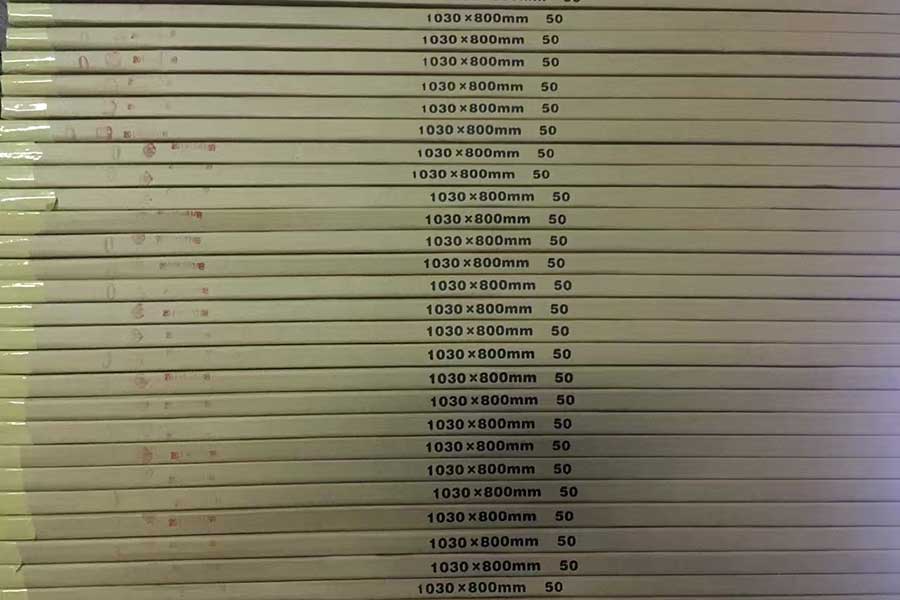

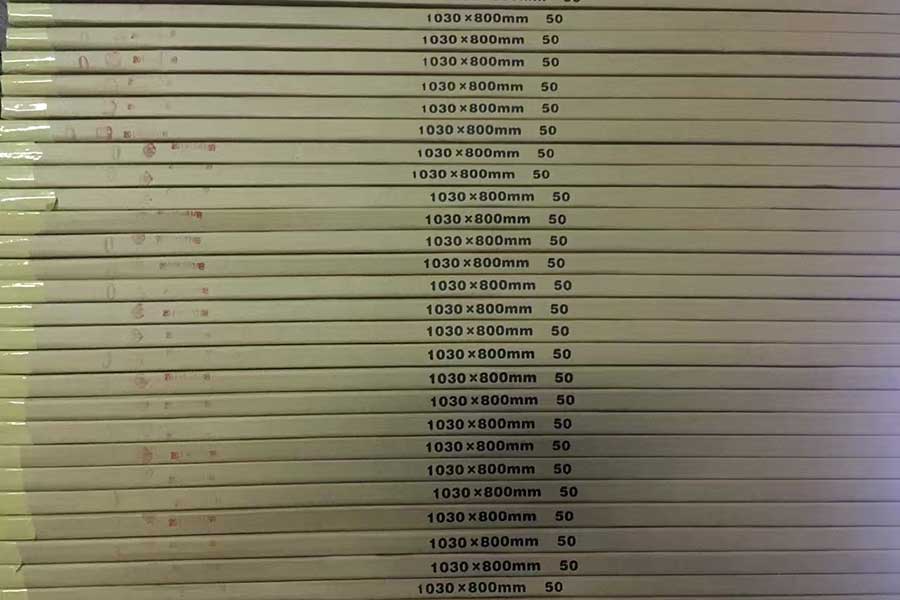

5.The Packaging of Positive Thermal CTP Plate

The packaging of Positive Thermal CTP Plate produced by our company: two coated faces are placed facing each other, separated by neutral backing paper in the middle, the outside is covered with plastic lined black kraft paper and placed in the carton box,each carton box is loaded around 50 -100 pieces,

Then stack the loaded carton boxes neatly on the wooden pallet and protect them with wooden frames or cardboard.

Finally, wrap it with kraft paper or plastic film and tighten by plastic tapes.

Or Packed according to customer requirements.

CTP (computer to plate) refers to the technology that the graphic information on the layout is digitally processed and output directly to the printing plate without going through the process of making the film. The pre-press staff does not need to output the film after typesetting, and directly forms the image through the CTP plate making machine to the CTP plate, it is convenient to realize the full digital workflow from pre-press to printing and post-press.

Henan Chalco’s Positive Thermal CTP Plate combines all the excellent performances, high sensitivity, high print resistance, and UV-resistant ink. It is an ideal choice for high-end printing users.

2, The Technical Parameters of Positive Thermal CTP Plate

Product Name: Positive Thermal CTP Plate

Alloy temper: 1060, 1050A, 1100 H18

Thickness: 0.15mm- 0.4mm

Available specifications: various specifications, or according to customer’s specifications

Maximum width: 1350mm

Spectral Sensitivity/Photosensitive wavelength: 800-850nm

Sensitivity/Exposure energy: 100-130mj / c㎡

Resolution: 1-99%

Developing temperature 23 ± 2 ℃

Developing time:20-30 seconds

Safety light: The safe operation time of the room can be 2-4 hours

Run Length: 50,000-100,000 impressions (Unbaked) 100,000-200,000 impressions (Baked)

Shelf life: 24 months

Storage conditions: temperature 5-30 ℃, humidity 40 ~ 80% RH, protected from light, moisture, closed and stored, stack height <1.2m

3. The Product Advantages of Positive Thermal CTP Plate

1) The Positive Thermal CTP Plate produced by our company has strong stability

Our company has advanced production technology and strict quality control management to ensure the stable and consistent product performance and to ensure the high quality and stability of printed products.

2) The Positive Thermal CTP Plate produced by our company has fast plate-making speed, low energy and high speed, which maximizes the production capacity of the equipment and improves work efficiency.

3) The Positive Thermal CTP Plate of the dots produced by our company is accurately restored without correction, and the dot error does not exceed 1%. The application range of the equipment is expanded and the quality of plate-making is stable. It is perfectly suitable for plate-making equipment of 800 ~ 850nm.

4) The Positive Thermal CTP Plate produced by our company has high run length, and can reach 100,000 impressions without baking, and 200,000 impressions after baking.

5) The Positive Thermal CTP Plate produced by our company is easy to use. It operates in a bright room, does not require preheating, has high tolerance and strong adaptability, is not easily affected by changes in the working environment and operation, and is convenient for storage and transportation.

6) The Positive Thermal CTP Plate produced by our company reduces printing cost, high plate-making speed, high work efficiency, good water-ink balance performance, less paper consumption, fast ink application, and high ink use efficiency.

4, The Usage of Positive Thermal CTP Plate

The Positive Thermal CTP Plate produced by our company is compatible with all mainstream thermal plate-making machines in the market, and is widely used in packaging and exquisite commercial printing.

5.The Packaging of Positive Thermal CTP Plate

The packaging of Positive Thermal CTP Plate produced by our company: two coated faces are placed facing each other, separated by neutral backing paper in the middle, the outside is covered with plastic lined black kraft paper and placed in the carton box,each carton box is loaded around 50 -100 pieces,

Then stack the loaded carton boxes neatly on the wooden pallet and protect them with wooden frames or cardboard.

Finally, wrap it with kraft paper or plastic film and tighten by plastic tapes.

Or Packed according to customer requirements.

CTP PLATES

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan